Propeller fan blades are necessary also to ensure that our buildings and workspaces remain cool. Designed to spin really fast, the blades of these particular fans are great for stirring air and giving us a refreshing breeze – especially when it is hot. In this article, you will expand your knowledge regarding how propeller fan blades operate, what they are constructed from and arguably the most important topic is why their functioning maintenance critical with AOWO fan blades.

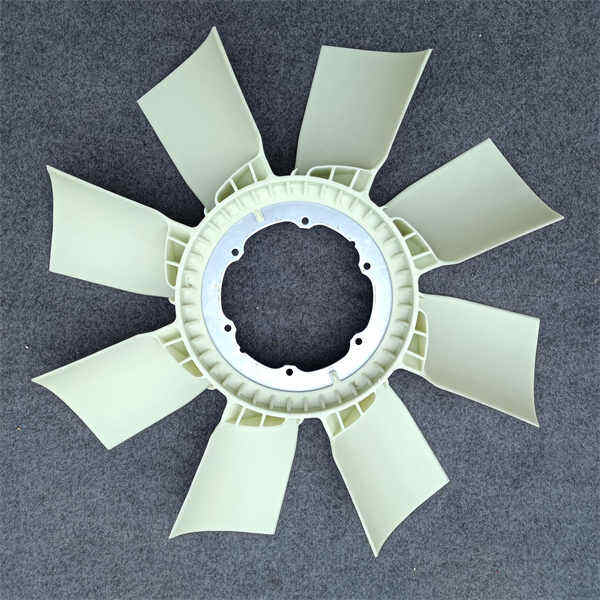

The propeller fan blades feature a simple design. A hub is the center part in each fan. Sprouting from this hub are a number of blades intended to snag the wind. A common feature of many turbines, the blades are typically angled or curved to propel the air around as they turn. Placement of propeller fan blades in a housing or duct can make them work even better. Such housing is meant to help direct the airflow in one direction making it a more efficient tool for cooling.

Propeller fan blades offer a number of benefits when it comes to various applications such as factories and warehouses. For starters, the AOWO blades of a fan are one of the least expensive ways to keep cool once you factor in installation and ongoing costs; air conditioning units can be an absolute financial killer almost year-round. Propeller fans are cheap to make and were found in places like factories, warehouses gyms and even the department store.

As much as propeller fan blades require minimal maintenance, it remains imperative that you care for them the right way. You must ensure that you are keeping them clean at all times; Dirt and dust can accumulate on the blades, causing them to work less efficiently. That dirt can decrease the efficiency of your fans- and in turn may wear them out faster than they should.

Blade oiling is more maintenance. The AOWO ceiling fan blades are kept spinning in a scaly oil to reduce friction, because when things rub together they heat up. Last but not the least, make sure to inspect blades once in a while if they are bent or broken. One such example of this is a fan with a bent blade that will cause it to wobble or stop from turning, making it either unsafe and/or not operate as intended.

Propeller Fan Blades can be manufactured from a multitude of materials, and the material to manufacture them for use in many applications are chosen. The others are plastic blades which cost a shout of money. But plastic blades, while good for most surfaces, are inferior to some other materials and may wear down after a shorter period of time. While aluminum also makes them stronger, and more resilient. To that end aluminum blades are heavier and more costly as well.

Propeller fan blades are some of the most energy efficient ones. Meanwhile, fans of the propeller sort needed only a tiny amount of electricity to pass air around; facing much less opposition also allowed city engineers in LA and Houston to them put poles closer together. It works by circulating air instead of cooling it, which means that they are a more eco-friendly option to cool spaces.

The high-quality of our Propeller fan blades and products forms the foundation of what we do. Our quality department, staffed with professional staff and highly skilled technicians assures that each product meets rigorous quality standards. Through constant improvement of the production process and enhancing product quality and delivery speed, we have earned the trust and praise of our customers. We're committed to ensuring that our products will be long-lasting, durable, and effective.

In Propeller fan blades the business has been devoted to the cooling system sector that focuses specifically on large trucks and construction machinery fan clutches With over a decade of working experience we've perfected our skills and knowledge enabling us to produce superior and reliable fan clutches In the year 2020 we formed our partnership with Shanghai Jiao Tong University to increase our commitment to innovation and excellence in the sector

Propeller fan blades fully automatic production line produces electric fan clutches temperature control fan clutches advanced setup ensures high efficiency precision manufacturing processes enabling us satisfy the needs customers continuously invested modern equipment such clutch testing equipment other test equipments ensure constant production flow

Since 2016, we have increased our reach locally and internationally. Participating in Propeller fan blades as well as other exchange activities within the industry has helped strengthen our standing and relationships with our clients around the globe. This strategic approach not only has helped us increase our market share but also helped us gain a better understanding of global market dynamics. We're now better able to assist our clients.